Reliability Management Overview

Reliability is the ability of a system or component to perform its required functions under stated conditions for a specified period of time.

Why is Reliability Management Important?

Reliability Management should provide the right decisions to optimise the delivery of value. The objective is to ensure the optimised balance between reliability, availability, maintainability and safety of all assets, at optimal cost and under satisfactory conditions of quality, safety and protection of the environment, maintaining the resources of the company so that operations proceed effectively and efficiently.

Reliability Management includes the design for reliability, operability, maintainability, safety (ROMS), the revision of maintenance and calibration plans, based on the criticality and failure history, condition of the asset and criteria for creating.

Reliability Management supports the asset reliability optimisation, considering the design for ROMS, criticality and condition of the assets by using the most appropriate tools and techniques for supporting the development and revision of maintenance plans. Technology innovations are driving businesses to transform the traditional way of work in Reliability Maintenance using digitalisation, and the concepts of the Industrial Internet of Things (IIoT). This can utilise predictive maintenance and failure predictions which contribute to managing risk and improving cost, performance, quality and safety.

Reliability Management Approach

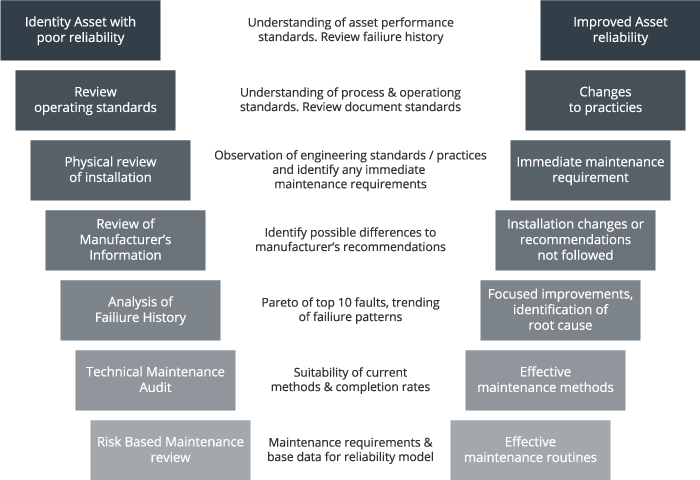

MCP’s holistic approach to reliability improvement ensures all contributory factors are investigated and appropriately addressed. The process follows a top-down and bottom-up approach and is described below:

The approach ensures factors such as:

Design

Quality of installation

Environment

Operating methods and standards

Support availability e.g. technical knowledge, spare parts provisioning etc

Effectiveness of Preventive Maintenance routines

The process actively engages with the maintenance, operations and project staff of the organisation, ensuring sustainable improvements are made for both existing and new installations.

Reliability Management Benefits

Our approach to reliability improvement has delivered substantial, tangible benefits to our clients in the areas of:

Increased uptime of assets

Reduced annual maintenance expenditure

Reduced inventory

Capital avoidance – improved asset performance has led to the canceling of planned capital projects often saving clients > £1m

Improved project delivery through a better understanding of Early Equipment Management needs

The approach also delivers intangible benefits, including:

Improved understanding of asset capability

Improved team working between maintenance, operations and projects through sharing of understanding

Improved utilisation of maintenance skills; maintenance technicians spend less time ‘fixing’ problems and more time preventing them

Speak to one of our Reliability Consultants today.